By collecting reliable data you enable more than just your savings

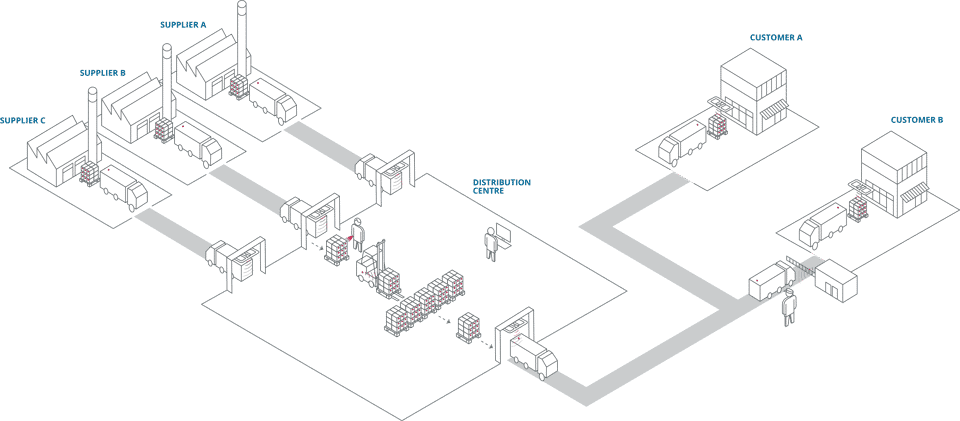

Transport Optimization is about automation through Artificial Intelligence and Machine Learning. Making business decisions based on scattered manual scanning and predicted track and trace is history now. We have a long legacy in collecting, processing, and analyzing business-critical data for postal operators in quality measurements for the letter and e-commerce business. With our Transport Optimization concept, we take it to the next level.

Key-value drivers:

Save at least 10% on your transport budget and be more flexible in your daily operations

Responsible use of resources to reduce CO2 emissions and fuel consumption

Business decisions are based on reliable real-time data

100% automated collection of real-time location tracking data of containers

Three good reasons to learn more about transport optimization

1: Using analytics for better decision-making

- Obtain exact real-time knowledge about the actual fill rate on routes

- Enable route optimization by using predicted analytics

- Enable advanced vehicle capacity optimization

2: Accomplish cost reduction

- Use real-time tracking data to monitor the actual fill rate

- Analyse the data and learn how to make permanent adjustments and raise fill-rate

- Use the data in daily operation to be flexible and foresighted

3: Unleash the power of your existing equipment

- Use existing Exiter/RFID infrastructure in sorting centers

- Load control prevents mis-shipment

- Automated nesting enables item tracking and exact volume forecast

Optimize your transport

Get on track!

Prepare for Holiday Season with Transport Optimization

Learn how you can navigate the busiest time of the year – the festive period – with ease through the adoption of transport optimization technology.

Enhance customer experience through real-time location tracking

- Know the exact item location in true real-time with 30 seconds ping

- Best fit technology across the whole value chain and customer edge

- Out of network tracking using LPWAN with ping a few times each day

Replace manual scanning with an automated association of parcels to containers

- Manage full containers in the automatically assigned direction

- Single item visibility based on nesting technology

- Real-time customer notifications on item status and arrival time

Save 10% on transport optimization

Find More Inspiration