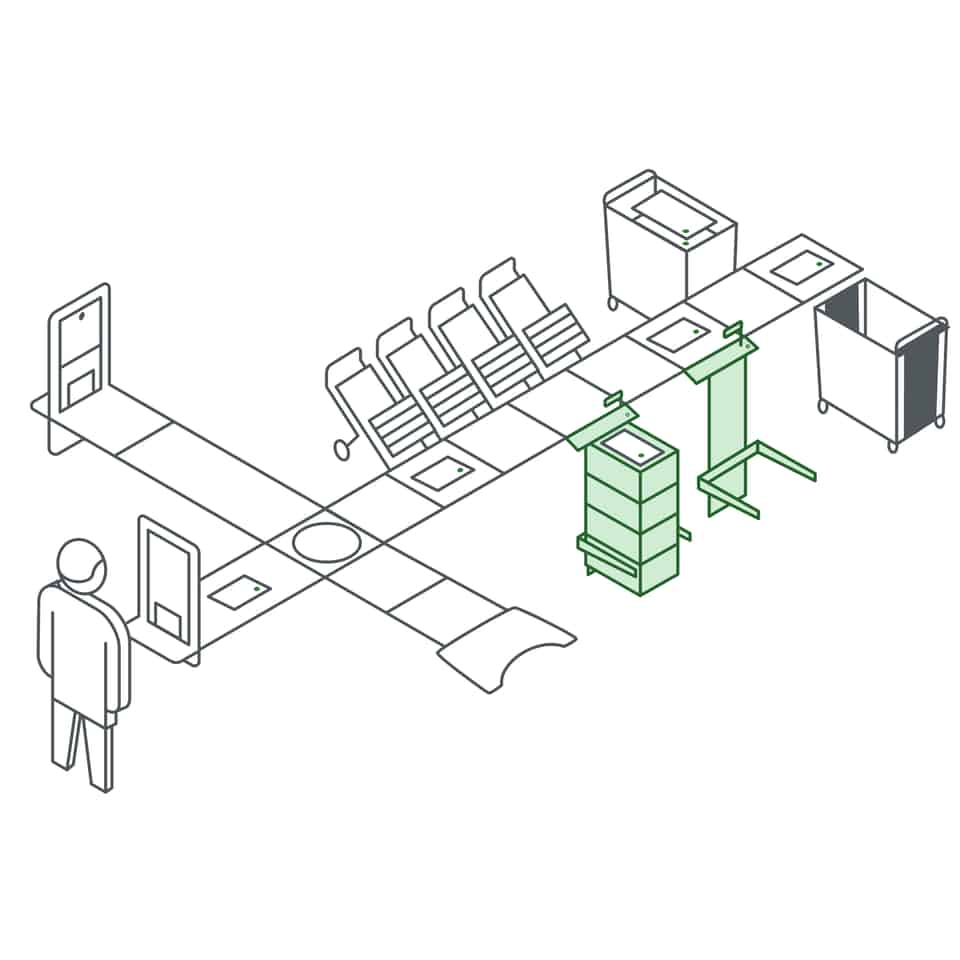

Lyngsoe Automatic Tote Stacker - Efficient Library Logistics Without the Heavy Lifting

Designed to attach seamlessly to the Lyngsoe Sort Mate™ 2000 module, the Lyngsoe Automatic Tote Stacker™ allows library staff to build stacks of totes with the touch of a button.

Discover the Advantages of Tote Stacker Chute

Eliminates the need for physical lifting

Build stacks destined for the same location for a smooth logistics process

No manual oversight needed, push a button and walk away

Built to accommodate your preferred tote configuration

Want to know more? Download the Automatic Tote Stacker product sheet for specification details and technical information

Turn the Page on Your Library Operations

Get in touch to hear more about how a tailored solution can help your library reach its full potential.

See What Others Were Interested In

Tote Shelf

Crafted for swift accessibility and efficient organization, it's the go-to solution for managing library totes. Capitalize on space with precision.

Lyngsoe Tote Check-in Server™

Lyngsoe Tote Check-in Server streamlines the check-in of bulk materials, ensuring rapid and accurate processing of library totes.

Split Chute

Maximize sorting efficiency with Split Chute. This solution directs returned items to multiple destinations, streamlining your workflow like never before.

Library Case Stories

From Manual Handling to Streamlined Efficiency

As Marigold Library System faced growing volumes, the Sort Mate™ 2000 proved invaluable in streamlining sorting and improving daily workflows.

Automation Increases Meaningful Patron Time

When Svendborg Library decided on an automatic book sorter, the decision was rooted in a desire to improve working conditions for staff as their circulation numbers rose. With the sorter, manual labor was decreased while the staff gained time for more meaningful patron interactions – something the library believes will secure their survival in the future.

Managing Growing Return Numbers with Automated Book Sorting

As Nørrebro Library continues to experience a rise in their circulation numbers, the implementation of a small sorting system onsite has been invaluable to the functionality of the library.

Numerous Benefits to Automating the Library Return Process

“The partnership with Lyngsoe Systems was very service-oriented. We were able to rely on the team’s professional and competent advice during both the planning and implementation of Lyngsoe’s products.”

Automated Library Item Induction & Destacking – Lyngsoe Systems

Destack books effortlessly with Lyngsoe Ergo Feeder™ 2000, enabling you to speed up sorting and free up your staff for more important tasks. Learn more.

The Lyngsoe Metal Bin - Efficient bulk material collection in libraries »

The Lyngsoe Metal Bin is tailored to meet challenges with bulk material collection and transportation where both material safety and staff well-being are prioritized.